- Home

- Innovation powerhouse

- A future-proof chemical industry

A future-proof chemical industry

Antwerp’s ecosystem: an innovation hub for every sustainable chemistry entrepreneur

Antwerp’s ecosystem has an innovation hub for every sustainable chemistry entrepreneur, whether your technology readiness is low, high or somewhere in between. Antwerp’s strength? All innovation hubs are closely connected, ensuring a productive and suitable environment no matter the life stage of your business or innovation.

In recognition of Antwerp’s sustained efforts to create innovation hubs, the city received a prestigious award at the worldwide fDi Strategy Awards in 2020.

© Jonathan Ramael

BlueApp: your pre-incubator

Looking for a hub that offers everything you need to develop, scale up and demonstrate your promising innovation or technology? BlueApp, a pre-incubator at University of Antwerp, brings together startups, companies and the University of Antwerp’s expertise. Through a successful combination of suitable space, academic know-how and essential services, BlueApp supports your tackling of sustainable chemistry challenges in collaborative projects.

Brand-new building at Blue Gate Antwerp, a climate-neutral business park. This location offers many accessibility and logistics advantages. Incubator BlueChem is a neighbour.

BlueApp focuses on carbon recycling, circular water, clean air, electrochemistry, plasma technology, sustainable hydrogen and thermocatalysis, from proofs of concept and refinements (linked to University of Antwerp) to upscaling projects.

- Science labs and testing environments tailored to your needs

- Prototyping lab

- Environmental lab

- Pilot hall

- Reliable partners for projects

- Benefits of multidisciplinary network

- Coaching and training options

- Flex desks for researchers and companies

- Oxylum is developing green technology to convert CO2 into sustainable chemicals.

- D-CRBN uses plasma technology to convert CO2 from flue gases into new raw materials for industry.

- Fairbrics transforms captured CO2 into polyester.

- BlueApp is a matchmaker for researchers and companies

- Founded by University of Antwerp

- Aimed at startups, scale-ups, corporations and researchers

© Victoriano Moreno

BlueChem: your incubator

Looking for a place for your startup or scale-up to grow and innovate? BlueChem helps you to develop sustainable innovations for the chemistry of the future through industry, academic and government connections. Spontaneous cross-pollinations, innovation projects and collaborations emerge in state-of-the-art labs and office spaces. BlueChem’s announced expansion will double its lab capacity and serves as proof of its success.

Blue Gate Antwerp is a climate-neutral business park. Its location offers many accessibility and logistics advantages. Pre-incubator BlueApp is a neighbour.

BlueChem focuses on innovation in sustainable chemistry, specifically on bio-based value chains, process intensification and transformation, circularity and resource efficiency and advanced sustainable products. With Catalisti as the site’s spearhead cluster for chemistry and plastics, access to promising innovative projects is close at hand.

- Unique network

- Direct access to renowned research centres

- Collaboration with leading global companies such as Air Liquide, BASF, Borealis, ExxonMobil, Ineos and Vopakl

- 3,375 m² of floor space

- “Ready-to-use” labs

- Labs set up as required

- Flexible workspaces

- Furnished offices & meeting rooms

- All-in service package

- Access to advice of all kinds (strategic, financial, environmental, safety)

- Funding support

- HR management

Tailor your innovation space to meet your specific needs. Thanks to the City of Antwerp’s BlueChem Kickstart Fund, you can have a laboratory subsidised up to EUR 1050 per m2 and up to 80% of your total costs to set it up. That includes purchases of cutting-edge technologies, state-of-the-art machinery and specialist laboratory equipment. Who knows, maybe even the flux capacitor you’ve always dreamed of!

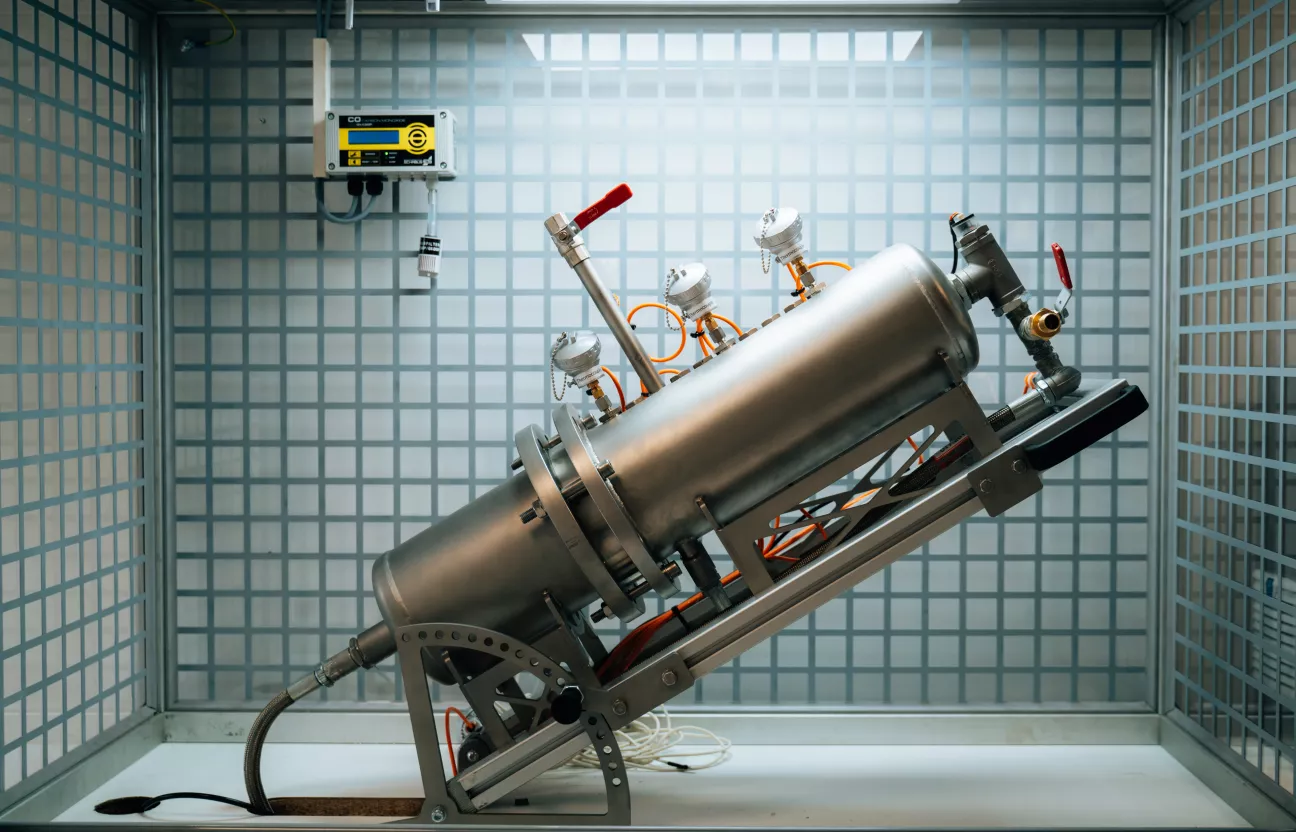

- D-CRBN has developed an innovative process that uses plasma to split CO2 molecules into their original building blocks for reuse in valuable products.

- Aquature’s innovative water treatment technology uses renewable energy and a bio-electrical process to treat industrial wastewater.

- Inopsys offers solutions to purify water and recover valuable components (metals, solvents) and helps customers in the chemical and pharmaceutical industries to work towards a circular economy.

- Belgium’s first incubator for sustainable chemistry

- Partnership between essenscia (Belgian Federation for Chemistry and Life Sciences Industries), City of Antwerp, research organisation VITO and POM (Provincial Development Agency)

- Aimed at startups, scale-ups, large enterprises, research centres and knowledge institutions

© Port of Antwerp-Bruges

NextGen District & Demo: your circular economy hub

Are you involved in the circular and climate-neutral chemistry industry? Discover NextGen District, an industrial port site that focuses on sustainable innovation, recycling and waste valorisation. Proximity to Europe’s largest petrochemical cluster offers your company a competitive advantage. NextGen Demo is a catalyst for sustainable innovations, particularly for pioneers in this field.

Industrial site in the Antwerp port area, close to Europe’s largest chemical cluster. This location encourages interaction with chemical companies and suppliers.

NextGen District & Demo focus on transforming waste into new raw materials and energy, offering significant cost advantages, reducing external dependency and delivering crucial environmental benefits.

- Vibrant hotspot brimming with new ideas

- Focus on creative entrepreneurship

- Heart of Europe

- Excellent multimodal connections

- Multiple innovation zones designed to meet your needs

- NextGen Demo offers you support and space to demonstrate your technologies on a larger scale

- Interaction with existing companies and suppliers

- Triple Helix is a circular factory for recycling of polyurethane foam and PET dishes and a BlueChem resident.

- Bolder Industries repurposes the chemicals in end-of-life tyres for supply chains and new products.

- PureCycle will be building its first European polypropylene recycling facility at NextGen District.

- NextGen District & Demo is a hotspot for the circular economy, alongside Europe’s largest chemical cluster

- Founded by Port of Antwerp-Bruges

- Aimed at the circular industry

© Schmitt

Blue Gate Antwerp: your circular industrial site

Is your innovative company committed to linear growth through the adoption of a circular business model? Blue Gate Antwerp is a circular industrial site covering 63 hectares to the south of Antwerp. This eco-effective, water-bound business park aims to maximise resource efficiency and minimise waste generation by implementing innovative practices and technologies. Blue Gate Antwerp facilitates collaboration among businesses, research institutes and government bodies.

Right next to the city, in the economic heart of Europe. Location on the river Scheldt offers unique logistics and accessibility advantages.

Together with the like-minded businesses located here, Blue Gate Antwerp activates circular flows at the micro and macro levels for cost-efficient collaborations on and off-site.

- Climate-neutral business park

- 63 hectares

- Upgraded public spaces with healthy green zones and historic heritage

- Pooled innovation capacity

- Guided eco-effectiveness

- Smart logistics and distribution

- Docking for water-bound transport

- DHL Express uses Blue Gate Antwerp as a starting point for city-wide distribution using its Cubicycles.

- BlueChem is an incubator for sustainable chemistry.

- Montea is an expert in logistics real estate. Eco-efficient construction and property management are part of its DNA.

- Amazon’s first development in Belgium will serve the city centre and the wider Antwerp area.

- Belgium’s first eco-effective and shore-based business park

- Founders: DEME, DEC, Bopro, City of Antwerp, PMV and DVW

- Aimed at innovative companies with a clear ambition to achieve linear growth through circular operations

The hydrogen revolution starts here

Interested in hydrogen as a business opportunity or a way to decarbonise your chemical operations? You’ll feel right at home in Antwerp. The Port of Antwerp-Bruges plays a pivotal role throughout the hydrogen economy value chain, including production, import, storage, distribution and consumption. Are you interested in joining this green hydrogen ecosystem? Together, we will contribute significantly to decarbonisation efforts and the use of clean energy in Antwerp and beyond.

If you’re active in the chemical industry, you’ll know this is carbon-intensive. The Port of Antwerp-Bruges has always been a major energy port, closely involved in fossil-based energy. That is now changing, however. Hydrogen is an essential factor in the mix of solutions to achieve climate ambitions, and Port of Antwerp-Bruges is prepared to become Europe’s hydrogen hub.

To achieve a viable hydrogen economy, sufficient renewable electricity for hydrogen production is crucial. In Belgium, wind and solar energy are not sufficiently available, requiring renewable energy to be imported. This requires specific expertise. Deme, Engie, Exmar, Fluxys, Port of Antwerp, Port of Zeebrugge and WaterstofNet have signed a cooperation agreement to coordinate their expertise and move towards a Belgian hydrogen economy.

Plugpower is a hydrogen plant in Antwerp’s NextGen District that aims to produce green hydrogen by 2025. The HyoffWind Consortium in Zeebrugge is also currently constructing a factory to convert renewable energy into green hydrogen by 2025. In addition to local production, Port of Antwerp-Bruges invests in importing renewable energy from countries such as Chile, Oman, Namibia, Egypt and Brazil, where green electricity is abundant.

The Port of Antwerp-Bruges has the necessary infrastructure to receive and distribute hydrogen carriers, including docks, terminals and pipelines. The port actively invests in new infrastructure such as hydrogen storage tanks and the integration of hydrogen refuelling stations for various types of vehicles. Pipelines offer industry an environmentally friendly way to transport hydrogen and CO2. The port owns and controls 720 km of pipelines, 90% of which serve the chemical and petrochemical industries and those that depend on them. The port area contains over 1,000 km of pipelines managed by private companies and the Port of Antwerp-Bruges.

The chemical industry already uses hydrogen in refining processes and chemical production. This market is experiencing significant growth, driven by the potential of green hydrogen as a raw material for heat production and heavy transportation. By incorporating hydrogen into its processes, the chemical industry can reduce carbon emissions and transition to more sustainable practices.

© D-CRBN

Antwerp@C: carbon capture, utilisation and storage

To help reduce emissions, carbon dioxide can be captured from industrial operations before it ever has a chance to enter the atmosphere or removed directly from the air. Antwerp@C is an innovative CO2 reduction project initiated by the Port of Antwerp-Bruges in collaboration with seven leading chemical and energy companies: Air Liquide, BASF, Borealis, ExxonMobil, INEOS, Fluxys and Total Energies. This consortium aims to capture, store, and reuse CO2 to produce blue hydrogen, a significant step towards green hydrogen. The Antwerp@C project has the potential to reduce CO2 emissions in Antwerp by half by 2030. Captured CO2 is transported locally through pipelines and stored temporarily in a shared liquefaction installation.

Also interesting

Wouter Ducheyne - Qpinch

Europe’s largest integrated chemical cluster is a hub of innovation and sustainability

D-CRBN: Made-in-Antwerp climate technology with global potential

Port of Antwerp-Bruges, a port with a unique set-up

Wide open gates for tech innovation